It is crucial to ensure the security of all network information. Therefore, selecting a remote access SCADA solution with high-level encryption is paramount.

SCADA (supervisory control and data acquisition) software and hardware are essential components of automated control systems. Remote access to SCADA systems can be instrumental in controlling the operations of a plant or industrial facility. Electronic Team offers accessing SCADA components over a network with the help of Serial to Ethernet Connector integration.

Learn more about Serial to Ethernet Connector SDK integration and request a free trial by clicking the buton below. Read on to learn about the benefits of establishing remote SCADA access.

Serial to Ethernet Connector

Industry 4.0 status is not possible without creating remote access to SCADA. The goal of implementing remote access to SCADA is to reduce on-site repair costs, facilitate data exchange, increase competitiveness and simplify the decision-making process. The Electronic Team solution guarantees reliable security, which is an important factor when choosing a solution for remote access to SCADA

Industry 4.0 status is not possible without creating remote access to SCADA. The goal of implementing remote access to SCADA is to reduce on-site repair costs, facilitate data exchange, increase competitiveness and simplify the decision-making process. The Electronic Team solution guarantees reliable security, which is an important factor when choosing a solution for remote access to SCADA

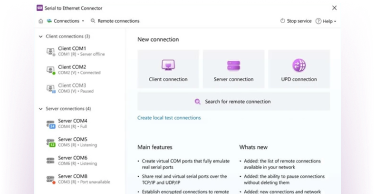

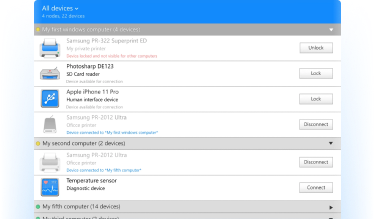

Serial to Ethernet Connector is a software solution that virtualizes network-attached serial devices such as PLCs, HMIs, industrial control equipment, and other types of peripherals so they can be accessed remotely. Integrating Serial to Ethernet Connector with the software component of a SCADA system enables communication between the control center and remote, network-connected serial devices.

Serial to Ethernet Connector unifies access to an organization’s control systems and devices attached to COM or serial ports. Many types of industrial equipment support connectivity through a COM interface. The software solution is beneficial to any organization that needs to connect to remote SCADA systems.

Serial to Ethernet Connector can be directly integrated into your existing SCADA system with its OEM/SDK. The software development kit provides the functionality needed to access COM ports remotely in the SCADA system. Our team offers additional development to address specific operating systems and requirements.

Serial to Ethernet Connector

FlexiHub