Submit your email address to get a link for quick download on your desktop and get started!

Remote Machining melds two seemingly antithetical concepts—control and freedom—so that shops can do some reconnaissance work or tweak parameters on their own terms. The manufacturer’s self-titled, all-hardware interface grants real-time access to all CNC functions via the Internet so that shop personnel can manipulate the process, regardless of their proximity to the actual machine.

One obvious issue with this approach is the potential strain this puts on the machines’ integrated circuitry, which is usually not intended to constantly run additional software. In the long run, the delay between commands could add up, extending the machining process by hours. But the remote control and diagnostics device can be external, and it can receive data and give commands through the same interface that the human workers use.

Nowadays at plants and factories you are unlikely to see machine minders actually bending over their machines and tools. Thanks to computer numerical control (CNC), the process of manufacturing is fully automated and designed to deliver 24/7. Moreover, it can be managed and manipulated remotely, regardless of the physical distance be tween operators and machines they work with.

How do they do it? Using specialized CNC machine software, of course. COM Port Redirector enables real-time access to a serial port of a CNC machine – an EDM, a water jet or a laser cutter, a lathe or a mill – over local network or Internet. This includes wireless RS232 CNC access.

How does it work? This CNC machine software creates a virtual serial port on a local computer, and the port starts mirroring all activities of a real port on a remote computer; it connects applications and ports via virtual null modem cable.

This CNC communications software can be used in various scenarios, the major three being:

Let us have a closer look at them.

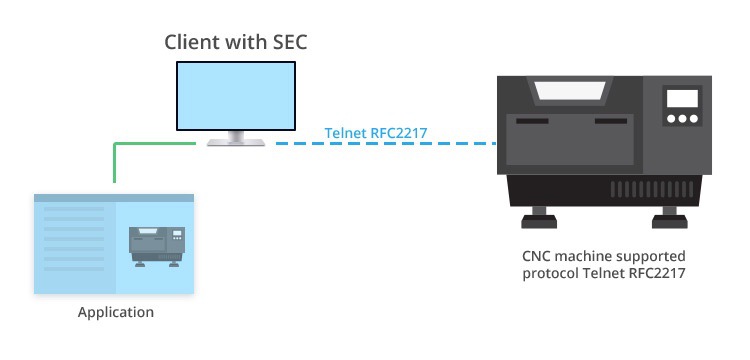

Say, there is a CNC machine you need to access from a local computer; the machine supports Telnet (RFC 2217) protocol. Install Serial to Ethernet Connector on your local PC and it will help you access the functionality of the remote CNC equipment as if it were connected directly to your local PC. It is not required to install SEC on the remote side.

The input/output data from a local virtual/ physical serial port can be rerouted over UDP/IP protocol, and all your serial data can be broadcast over local network.The input/ output data from a local virtual/ physical serial port can be rerouted over UDP/IP protocol, and all your serial data can be broadcast over local network.

Another data transmission protocol you can use for CNC file transfer instead of Telnet (RFC 2217) is RAW data transmission algorithm.

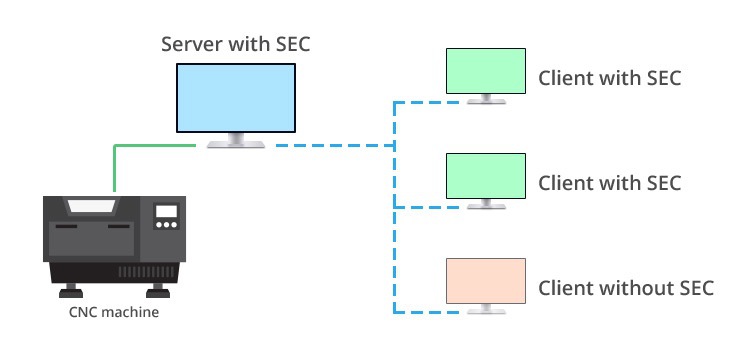

You have a CNC machine connected to your local computer and other network users would like to access it. Install Serial to Ethernet Connector locally, and this CNC program transfer software will enable you to share the equipment with others. Your local machine becomes a server that allows incoming connections from clients, the latter might or might not have SEC installed on them.

This works perfectly well if you would like others to get remote CNC access, including wireless CNC access, to your local device.

Related Articles

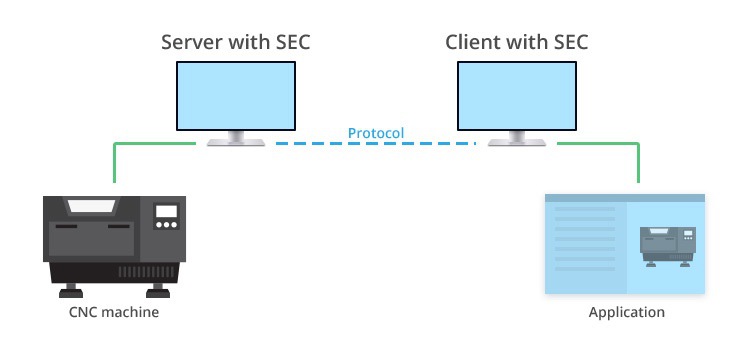

Here you connect CNC device to a real serial port on your local PC, and you would like to provide CNC remote control to an application on a target PC. In this scenario it is required to install Serial to Ethernet Connector on both computers: the RS232 control software creates a virtual serial port on the target computer, and the app connects to it and starts interacting with the remote CNC device. Thanks to Telnet as the underlay protocol, the application can manage all settings of the remote real port.

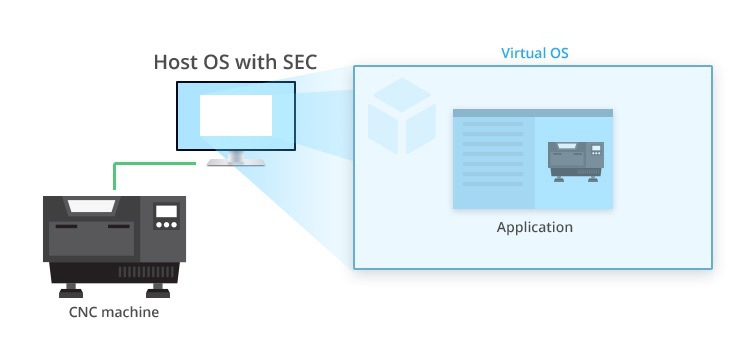

What do you do if a CNC machine is connected to your computer, and the app that needs to talk to your serial machine is not compatible with the OS that your computer runs on? However, your local computer can host a guest OS compatible with the application. To solve the issue, on the host OS (it acts as a server here) share a serial port to which the CNC equipment is attached, then create a virtual port on the guest OS (it becomes a client). Enter the IP address of the server (the network name will do too) and TCP port. Connect – now all data from the serial device will be redirected to the virtual serial port and processed by the application.

So these are the main scenarios of using Serial to Ethernet Connector for industrial purposes.

Conclusions

We have looked at some of the situations you are likely to encounter where Serial to Ethernet Connector will enable remote CNC access. You can see how the ability to access remote CNC machines from your office can make your job easier. This CNC remote control software from Electronic Team can also be used to gain remote access to PLCs. CNC over network technology can be incorporated into your own software product when remote access to industrial equipment is desired.

We would also like to emphasize that the company that develops this RS232 file transfer software has a significant experience in serial communication field and can optimize the program for specific use-cases – from integrating Serial to Ethernet Connector technology into your own software application to customized solutions.

SEC for Windows

SEC for Linux